Enquiry List () (0)

- 17 Apr 2017

Customised Emergency Safety Shower Solution for Extreme Azerbaijan Climate

Background: The Sumgait Chemical Industrial Park was established to accelerate economic development in Azerbaijan and to provide sustainable development of the non-oil sector. Incorporating 192 hectares of industrial infrastructure, the park has more recently welcomed the construction of a polypropylene and high density polyethylene (HDPE) plant by The State Oil Company of the Azerbaijan Republic (SOCAR).

This will be the first polypropylene plant of its size and scale in the petrochemical industry implemented in Azerbaijan over the past 40 years. The plant will utilise the propylene feedstock from an existing naphtha cracker at the site allowing a production capacity of 180,000 tonnes per annum, while the HDPE plant will have a production capacity of 120,000 tonnes per annum.

Objective: As would be expected within the petrochemical industry, health and safety is of great importance due to the high risk associated with the hazardous materials workers are exposed to. SOCAR Polymers were looking for an emergency safety shower solution which would ensure the water in the standpipe would be unaffected by potential solar radiation or freezing temperatures due to the extremes in the Azerbaijan climate.

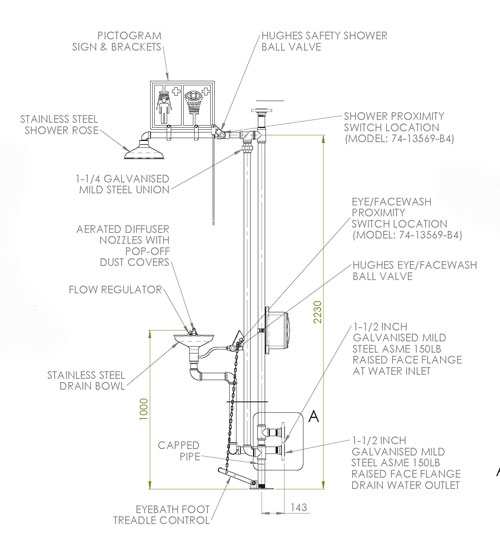

Solution: Working in conjunction with the Engineering Procurement Contractor, Hughes provided a customised solution - the EXP-18G/85G emergency safety shower with open bowl stainless steel eye/face wash units featuring a dual standpipe recirculating system to reduce the risk of overheating or freezing. The addition of an orifice plate will ensure a controlled, continuous flow of water through the standpipe at all times, whatever the conditions. Tepid water provision was also a significant design criteria, enabling the showers to be used for 15 minutes without users suffering thermal shock or scalding, and with the addition of a minimum flow rate of 87 litres per minute the showers meet the latest ANSI Z358.1-2014 requirements.

Project specific GO switches complete with cast aluminium Exd junction boxes were supplied to ensure the stringent Hazardous Area ATEX electrical requirements were complied with. Finally, to ensure the units would be suitable for the range of chemicals on site a corrosion resistant paint was applied, finished in RAL 6021, which met the project requirements.

The Hughes emergency safety showers will be on site in Azerbaijan in 2017 and the plant will begin operations in 2018.