Enquiry List () (0)

- 20 Jun 2019

Chemical Hazards in the Waste and Recycling Industry

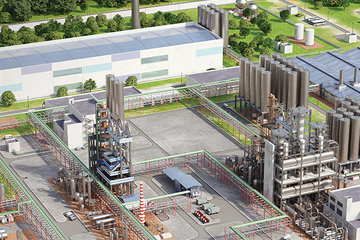

In the UK alone more than 100 million tonnes of waste are generated every year requiring an enormous workforce to sort and process this waste each day. The recycling and waste management industry is constantly growing and developing due to the need for innovative technologies and processes required to deal with increasingly dangerous waste.