Enquiry List () (0)

- 9 Apr 2024

Hughes' Tank-Fed Safety Showers – Rapid Emergency Response in Hazardous Environments

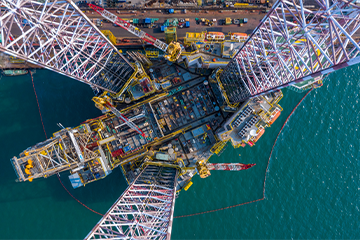

Selecting the right safety shower for your site can be a complex task. With challenges such as remote locations, extreme temperatures, low water pressure or no reliable water supply, a simple tubular shower isn’t always the right fit to adequately protect worker safety. From oil rigs to water treatment sites, petrochemical plants to mining facilities, emergency tank showers are the compliant solution for hazardous environments.

Self-contained and resilient, emergency tank showers are often the simplest and most comprehensive way to stay compliant to crucial safety standards.

Here are our top 10 reasons as to why you should choose a Hughes 1500L emergency tank shower:

- EN15154 and ANSI Z358.1-2014 Compliant

1500L tank showers are designed to meet the EN and ANSI requirements to provide tepid water for over 15 minutes at a guaranteed flow of 76 litres per minute for the shower and 12 litres per minute for the eye wash, simultaneously.

- No constant water supply? Low supply pressure? No problem

Our emergency tank showers are self-contained, gravity-fed units so do not need to rely on a plumbed in water source that may be inconsistent or not existent. No matter the limitations of your site, the unit supplies sufficient water pressure to provide a full 15-minute decontamination.

- Customisable to meet your exact requirements

Our range of tank showers has a wide array of optional extras to tailor your equipment towards your specific safety needs:

- Alarms, sirens and lights provide an additional level of safety for your staff by alerting first responders to the activation of a safety shower to provide signals for remote areas/lone works and lights for dimly lit areas and to ensure high visibility.

- GRP ladder platform offers increased safety for workers, conforming to working at height regulations, and removes the need to hire costly scaffolding when the emergency tank shower requires inspection or servicing.

- GRP Ramps prevent slips and trips on entering and enable easy access in the event of an emergency.

- Heaters and cooling options - In extreme hot or cold climates, heaters and/or cooling options are needed to ensure tepid water, between 15-37C according to EN15154 (ANSI recommends 16-38C).

- Hydroclenz water treatment system provides constant protection against the growth of harmful bacteria and legionella which can pose a threat in standing bodies of water. Chemical free, environmentally friendly, and cost-effective alternative to chemicals and UV treatments.

- GRP panelling - fitted to three sides of the tank shower support frame, these panels help protect the user against the elements during the showering process and provide privacy when clothing needs to be removed.

- Wireless monitoring ensures that in the event of an activation, responders are alerted instantly. Particularly useful for remote locations.

- Drain sumps are designed to contain the potentially contaminated used water from the shower and eye wash. For non-bunded areas water is drained away via a 2-inch drain outlet. Sumps are also effective to minimise slip hazards in the area.

- Doors and strip screens provide privacy whilst showering and help to prevent over-spray.

- Syphon dump valve automatically replenishes a proportion of the water in the tank on a regular basis to ensure the tank remains clean and reduces the risk of bacteria growth.

- Sunshields protect the water in the tank from the effects of heat transfer by conduction.

If your required product is not within our standard range, we have over 55 years of trusted knowledge and expertise manufacturing tailored solutions for unique site requirements. Simply submit your requirements to our team and we will contact you with our expert advice.

- Supply of tepid water whatever the climate

Our tank shower models can be supplied with an immersion heater and insulation to prevent freezing, or insulated only for hot climates to ensure a steady temperature is maintained.

Cooling options or heaters are necessary to ensure the provision of tepid water in extreme cold or hot climates. Flameproof chillers, non-flameproof chillers, and the award-winning Hughes Zero Power Cooler®, we have a cooling option to fit every application.

- Designed by experts to guarantee your safety

The polyethylene tank and GRP panelling allow for high corrosion and UV resistance, while the stainless steel tank shower frames are built in accordance with the California earthquake code to guarantee stability even in extreme climatic conditions.

- British made

Manufactured at our factory in the UK, the emergency tank showers are built to a proven design which ensures a long life. We’re also proud to have been awarded the ISO 9001:2015 certification, an internationally recognised standard that ensures our services meet the needs of clients through an effective quality management system.

- Simple to operate

The hi-visibility red panic bar and optional walk-on foot panel activation allow for quick and simple operation in an emergency.

- Lidded eye/face wash

Keeps bowl free from contaminants such as dust and debris from the surrounding environment.

- External test handle

Weekly activation of your safety showers and eye/face wash units is paramount to ensure all emergency equipment is operating properly. The external handle on our emergency tank showers enables quick and easy activation without you getting soaked!

- Product after-care

The benefits of buying a Hughes emergency tank shower don’t stop after the initial purchase. Hughes offer comprehensive service plans to ensure your equipment is fully operational if needed in an emergency. Our service contracts guarantee multiple visits from our experienced service engineers each year, completing a detailed site survey report to ensure your equipment works as intended. In addition, if you choose to have your equipment installed and commissioned by a Hughes service engineer your product warranty will receive a 12-month extension.

For challenging locations and applications, emergency tank showers are the ideal solution. With a Hughes tank shower, you can expect high quality manufacturing with the ability to tailor your safety shower solution to your specific needs.

To find out costs and availabilities of Hughes’ range of emergency tank showers, fill out our online enquiry form today and a member of our expert team will be in touch.