Enquiry List () (0)

- Jun 18, 2025

Specifying safety showers at wastewater treatment plants

Wastewater treatment plants are vital to public health and the environment, quietly processing the substances that keep our communities clean. Yet, behind the scenes, the essential work performed by plant personnel often involves exposure to significant hazards. From corrosive chemicals and toxic gases like chlorine to various biological contaminants, these environments present a constant risk of serious injury.

A chemical splash to the skin or eyes can lead to immediate pain, long-term damage or worse, making immediate decontamination a critical first line of defence. This guide will cover the need for emergency safety showers at wastewater treatment plants, outlining essential specifications, compliance standards and effective solutions to protect your workforce from these dangers.

Why Emergency Showers Are Important at Wastewater Facilities

The operational environment of a wastewater treatment plant inherently presents risks that necessitate robust safety protocols. Among the most important protective measures are emergency safety showers and eyewash stations, which serve as an immediate response to chemical or contaminant exposure.

Wastewater treatment processes involve the handling and storage of various hazardous substances. Personnel are regularly exposed to:

- Chlorine: used for disinfection, chlorine can cause severe respiratory issues, skin burns and eye damage upon contact.

- Acids and alkalis: used for pH adjustment and cleaning, substances like sulphuric acid, hydrochloric acid and sodium hydroxide are highly corrosive, leading to chemical burns on skin and irreversible eye damage.

- Hydrogen sulphide: a by-product of anaerobic decomposition, this gas is extremely toxic. While not directly requiring a shower for exposure, other associated irritants or splashes could need immediate flushing.

- Polymers and coagulants: used in sludge treatment, these can cause skin irritation or allergic reactions.

The impact of a chemical splash to the skin or eyes can range from immediate, excruciating pain to severe burns, irritation and potentially long-term or permanent damage, including blindness. Beyond chemical exposure, wastewater environments can also pose risks from biological contaminants, including bacteria, viruses and parasites. In instances of contact with raw sewage or aerosols, immediate and thorough flushing is essential to prevent infection and mitigate health risks.

Safety Shower Standards for Wastewater Facilities

For wastewater treatment plants, the benchmarks for emergency safety showers and eyewash stations are ANSI Z358.1. These standards are designed to ensure that emergency showering and eyewash equipment provides immediate, effective and continuous decontamination:

- Tepid water: standards specify a tepid temperature range to prevent hypothermia or scalding, ensuring the casualty can remain under the flow continuously for a minimum of 15 minutes.

- Flow rates: defined minimum flow rates ensure sufficient water volume for thorough flushing of the eyes, face and body. This prevents the chemical from being spread around rather than washed away.

- Activation time: equipment must be capable of activation in one second or less. This rapid response capability helps minimise damage post-exposure.

- Accessibility: safety showers and eyewash stations must be located within 10 seconds’ reach of any potential hazard.

Adherence to these specifications directly impacts the effectiveness of emergency response and, consequently, the severity of potential injuries. Non-compliance can lead to severe worker injuries, significant liabilities and reputational damage.

Types of Emergency Safety Showers for Wastewater Treatment

Selecting the right emergency safety shower is important for effective hazard mitigation and depends on factors such as facility layout, accessibility to utilities, climate conditions and specific hazard profiles:

Plumbed-in Units

Plumbed-in Units

Plumbed-in emergency safety showers are connected directly to a continuous, potable water supply, offering a reliable and high-volume flow for extended periods. Advantages include:

- Continuous water supply: eliminates concerns about water depletion during prolonged decontamination, ensuring the full 15-minute flush.

- High flow rates: typically provide the robust flow rates necessary for thorough body and eye flushing.

- Consistent tepid water: when equipped with thermostatic mixing valves or water heaters, they can consistently deliver water within the required tepid range.

Considerations should be made to the following:

- Plumbing infrastructure: requires access to a reliable water line and drainage. Installation can be more complex and costly where infrastructure is lacking.

- Freezing protection for outdoor units: in colder climates, outdoor plumbed units need specialised features like trace heating or heated enclosures to prevent water lines from freezing and rendering the equipment inoperable.

Self-contained Emergency Showers

For areas where access to a water supply is limited or non-existent, self-contained emergency showers offer an alternative. These units store their own water supply, making them versatile. Their independence makes them perfect for remote sections of a large plant, temporary work sites or newly established facilities awaiting permanent infrastructure.

Features include:

- Integrated tanks: equipped with large water tanks to provide the necessary 15-minute flush.

- Mobile options: available on trailers or with in-built wheels, these portable safety showers can easily be relocated to hazard zones.

Tank size must be carefully considered to meet the minimum flow rate for the full 15 minutes as per standard requirements.

Unlike plumbed-in units, self-contained units require regular maintenance to ensure the water quality and operational readiness. This includes periodic water changes to prevent bacterial growth and sediment buildup, as well as checking pressure and seals.

The Hughes 2000 litre emergency tank shower with eye wash is the perfect ‘all-rounder’. Whatever the location or climate, there is a model available to provide tepid water at a rate of 76 litres per minute for up to 15 minutes. The overhead tank stores 1500L of water, so it remains self-contained or can be plumbed into the main water supply.

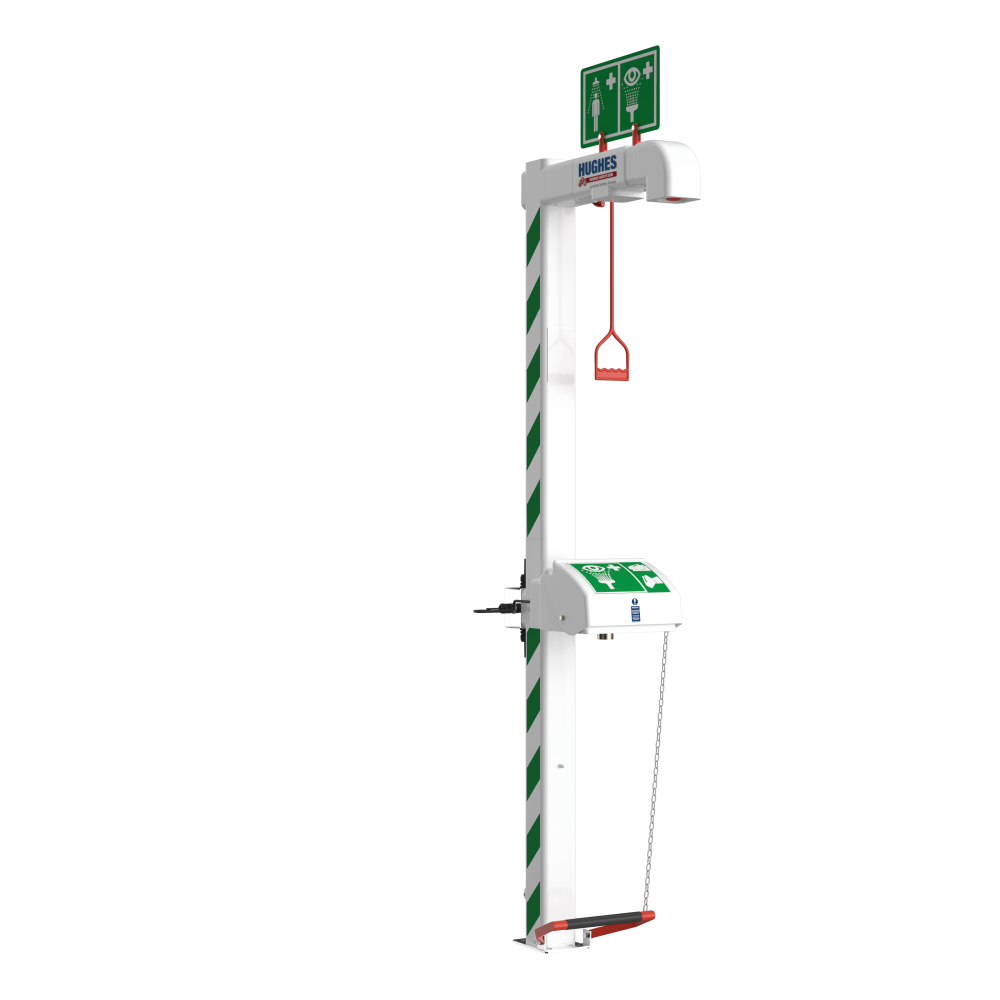

Combination Units (Shower and Eyewash)

Combination units integrate a full-body safety shower and an eye/face wash station into a single, compact fixture. These units are highly efficient, allowing a casualty to flush contaminated eyes/face while showering the body.

Specialised Solutions for Unique Challenges

Beyond standard configurations, specialised emergency shower solutions are available to address specific environmental and operational demands of wastewater treatment plants:

- Heated and cooled models for extreme temperatures:

- Heated showers: essential for outdoor installations in regions prone to freezing, these units prevent water lines from freezing and ensure tepid water delivery even in sub-zero temperatures. The immersion heated model (MH14KS2000) will maintain the water temperature within the tank in the tepid range.

- Cooled showers: for extremely hot climates, cooled or insulated units prevent the stored water from overheating beyond the tepid range, ensuring safe and effective decontamination.

- Corrosion-resistant materials for aggressive environments: given the presence of corrosive chemicals and harsh conditions, units constructed from durable, corrosion-resistant materials (e.g. stainless steel) are vital for longevity and reliable operation.

- Mobile decontamination showers: these are robust, often self-contained units mounted on skids or trailers, designed for rapid deployment to temporary sites, emergency response scenarios or areas undergoing maintenance where fixed facilities are unavailable. They ensure that even transient workforces have immediate access to life-saving decontamination equipment.

Protecting the workforce should be at the forefront of every employer’s mind. To discuss your specific site requirements with experts, contact Hughes today on +44 (0)161 430 6618 or via our online contact form.