Enquiry List () (0)

- Nov 8, 2018

Emergency Shower Stations for the Fertilizer Industry

The fertilizer industry uses extremely hazardous materials in their production processes. Common industry chemicals like anhydrous ammonia can cause burns and inhalation hazards. Others like ammonium nitrate pose a risk of fire and explosion. One of the most well-known industrial accidents in recent history occurred in West, Texas, in 2013. A fire and explosion at a Texas fertilizer plant killed 15 people and injured more than 160 others. It also destroyed hundreds of homes.

Having the right emergency shower stations and eyewash equipment for employees is a critical component to minimizing injuries caused by chemical exposure.

Challenges of the Fertilizer Industry

1. Remote locations

Fertilizer plants often stretch out over large geographic areas. At site extremities, low water pressure may be an issue that puts workers at risk. The ANSI Z358.1 standard specifies emergency shower stations should provide a water flow rate of at least 20 U.S. gallons (76 liters) per minute, along with an eyewash that provides water flow of at least 3 GPM, for 15 minutes. Flow rates that are too low may not completely wash hazardous chemicals off the skin, leading to chemical burns.

In addition to low water pressure, some remote sites may not have a water supply at all, in which case a shower with its own water supply would be required. Because the equipment’s electrical components could potentially cause an arc, it would qualify as a hazardous environment which might necessitates Class 1 Division 2 electrical classification.

2. Extreme ambient temperatures

Fertilizer plants are often located near natural gas sources due to their need for hydrogen as a raw material. These locations are often hostile environments with extreme ambient temperatures. ANSI Z358.1 requires the water temperatures of emergency safety shower stations to be in the tepid range of 60 to 100 F (16 to 38 C). Water that is too hot may scald an injured person or cause their skin to absorb chemicals at an increased rate. Cold water can lead to hyperthermia, or even thermal shock. If the water temperature is tepid, workers are less likely to exit the shower early due to discomfort.

To prevent further injury to the skin when flushing chemicals such as ammonia, the water temperature must fall within a very specific temperature range – 77 to 86 F (25 to 30 C).

Emergency Showers Suitable for the Fertilizer Industry

Emergency tank showers have integrated tanks. They ensure adequate water pressure and flow when water supply is unreliable or unavailable. These showers meet the ANSI standard of 20 gallons (76 liters) per minute flow for 15 minutes. Thermal insulation on water tanks may be enough to prevent temperature fluctuations outside the tepid range. In extreme cases tank heaters and chillers provide the control measures needed.

Temperature controlled showers keep water supply in the tepid range regardless of ambient fluctuations. Heaters raise the temperature during cold nights, while chillers reduce the temperature during hot days. A release of liquid ammonia can freeze clothing onto the skin due to the extreme cold. Again, maintaining water temperature within the specified range is the only way to thaw the affected areas for removal of clothing.

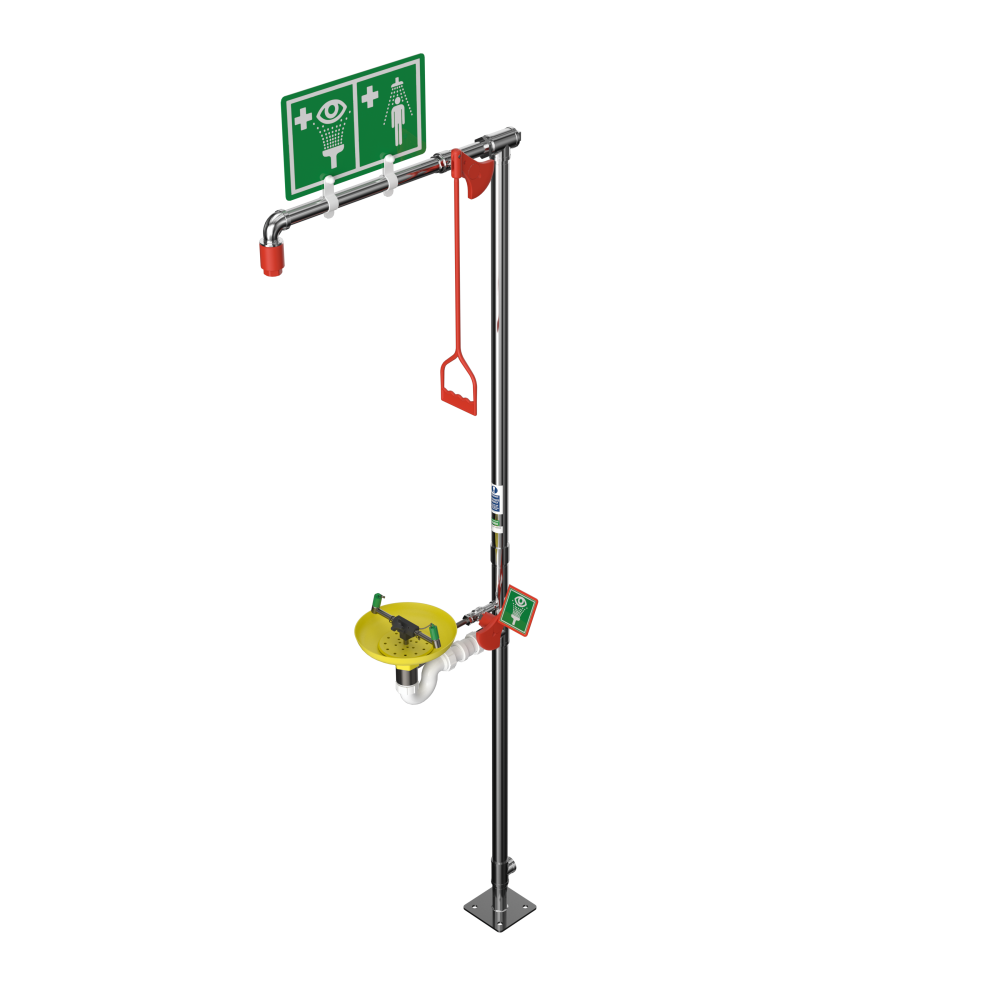

Hughes Floor Mounted Outdoor Emergency Safety Shower with Eye/Face Wash – Self-Draining for Hot Climates

Hughes Floor Mounted Outdoor Emergency Safety Shower with Eye/Face Wash – Self-Draining for Hot Climates

In hot climates, static water in pipes can rise as high as 122 F (50 C) due to solar radiation. Self-draining showers drain water from the standing pipes after each activation. This prevents exposing workers to extremely hot water upon activating the safety shower.

Hughes Safety Shower Stations Provides Industrial Safety Shower Solutions

Hughes Safety Showers is a leading supplier of emergency shower and eye wash equipment. Our technical experts can advise on the best emergency safety shower or eyewash equipment for the fertilizer industry. All of our equipment meets ANSI requirements. In addition, we offer inspection and other services for your safety setup to help you remain compliant. Find out more about Hughes Safety solutions here.

To learn more about ANSI requirements, download our free tech guide to the ANSI standard.