Enquiry List () (0)

- Aug 1, 2018

When and Where to Use Emergency Tank Showers

Emergency safety showers are used in a wide variety of industries. They are critical pieces of safety equipment for providing immediate relief to employees splashed with chemicals.

It may seem simple to provide a shower for this purpose, but it is not always as easy as connecting potable water to an industrial shower. Depending on the type of fixture that is needed, based on the hazard present, the emergency shower and/or eyewash/eye-face wash must meet the ANSI/ISEA Z358.1 standard. They must supply tepid water (defined at 60 F to 100 F) at a minimum flow rate of 20 GPM (safety shower), .4 GPM (eyewash), or 3 GPM (eye/facewash) for a period of 15 minutes. However, there are challenges to meeting these requirements.

Hurdles to Overcome in Meeting the ANSI Standard for Safety Showers

1. Harsh Climates

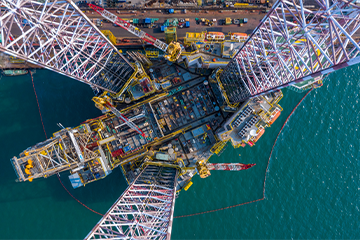

Oil and gas fields or petrochemical facilities need to be close to their raw material supply. Many of these sites operate in extreme conditions like the freezing cold Arctic region or the intense heat of the Middle East. The extreme ambient temperatures make it difficult to supply water in the tepid range.

2. Large Geographic Areas

Industrial facilities often extend over a large geographic area. Potable water lines must stretch across the entire site. But, there will inevitably be some areas where the water pressure is low due to the long distances involved. Low water pressure results in inadequate flow to emergency safety showers. Non-insulated piping can also affect the tepidity of the water. This may cause scalding temperatures during summer solar loads, or freezing in the winter if piping isn’t heat traced as well.

3. Plant Expansions

Over the years of their life, production facilities require expansions and modifications to keep pace with production needs and product changes. Each time this happens, demand rises on their central utility systems. Eventually, plants may reach the capacity of their potable water supply. Adding another emergency shower becomes challenging in these conditions and may not perform to the Z358.1 standard.

RELATED ARTICLE: Emergency Safety Shower and Eye Wash Stations, are yours ANSI Compliant?

The Advantages of Emergency Tank Showers

Emergency tank showers solve these challenges in meeting the ANSI standard. Tank safety showers feature an integral water tank which is filled with potable water.

Temperature control depends on the climate conditions. Insulation minimizes energy waste, while heating or cooling systems provide temperature control. In other words, an emergency tank shower is a self-contained unit able to supply tepid water even in remote locations so that users receive the immediate relief they need after a chemical splash.

Examples of Emergency Tank Showers in Use

The popular Immersion Heated 2000L Emergency Tank Shower is suitable when low ambient temperatures make it impractical to use a standalone safety shower. With a tank capacity of 528 gallons (2000 liters), it provides a tepid water flow of 20 gallons (76 liters) per minute for the shower and 3 gallons per minute for the eyewash for 15 minutes. Heaters and dual thermostats ensure water temperature remains in the tepid range by using immersion heaters and chiller units for both hot and cold climates.The Tengiz oilfield in Kazakhstan is in one of the harshest environments in the world. Temperatures range from minus 49 F to 113 F (minus 45 C to 45 C), making it very difficult to supply potable water in the tepid range. Hughes Safety provided Tengiz with Polar Emergency Tank Showers. The additional benefit of an enclosed cubicle means that the casualty remains in a safe and comfortable environment until help arrives.

RELATED ARTICLE: Combatting Bacteria Growth in Emergency Tank Showers

Contact Hughes Safety Showers for Your Emergency Tank Safety Showers

Hughes Safety has extensive experience in solving the challenges of meeting the ANSI requirements for safety shower equipment. We work with site engineers to provide solutions that keep employees safe and emergency showers compliant. Download our free ANSI guide here or browse our range of safety or emergency tank showers here.