Enquiry List () (0)

- 28 Mar 2025

Avoid Liquidating Safety Procedures: LNG Processing Hazards & How to Protect Your Workforce

Natural gas currently makes up about a quarter of the world’s energy provisions. In a global effort to reduce our carbon emissions, more and more countries are turning to liquefied natural gases (LNG) as an alternative to traditional fossil fuels. LNGs emit 30% less carbon dioxide than oil and up to 60% less than traditional coal plants.

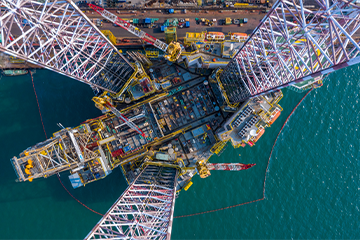

Natural gas is primarily composed of methane, usually between 70-90% of the compound, which is so light in its composition that it’s even lighter than air. In its gaseous state, the fuel takes up significant storage space compared to that of a liquid. It, therefore, undergoes a liquefication process, so that much higher quantities of fuel (approximately 600 times as much) can be stored and transported. For this to happen, the gas must be cooled to -162C/-265F within containers and pipes that are cooled using nitrogen. The liquefied gas is then commuted to a specialised tanker, which can take the fuel to its end destination for processing.

Throughout the process, the liquefied natural gas is transported through pressurized pipes and specialist cargo ships. Due to the high pressure, there is a constant threat that any of the pipes could spring a leak. The pressure would cause the LNGs to be ejected at a high velocity, quickly dousing any nearby workers. As a protective measure, all workers involved must wear appropriate clothing and gloves to protect their skin from any contact with the product. Due to the intense cold of LNGs, if the skin is exposed to them, it can cause extreme and permanent damage to the skin through cryogenic burning.

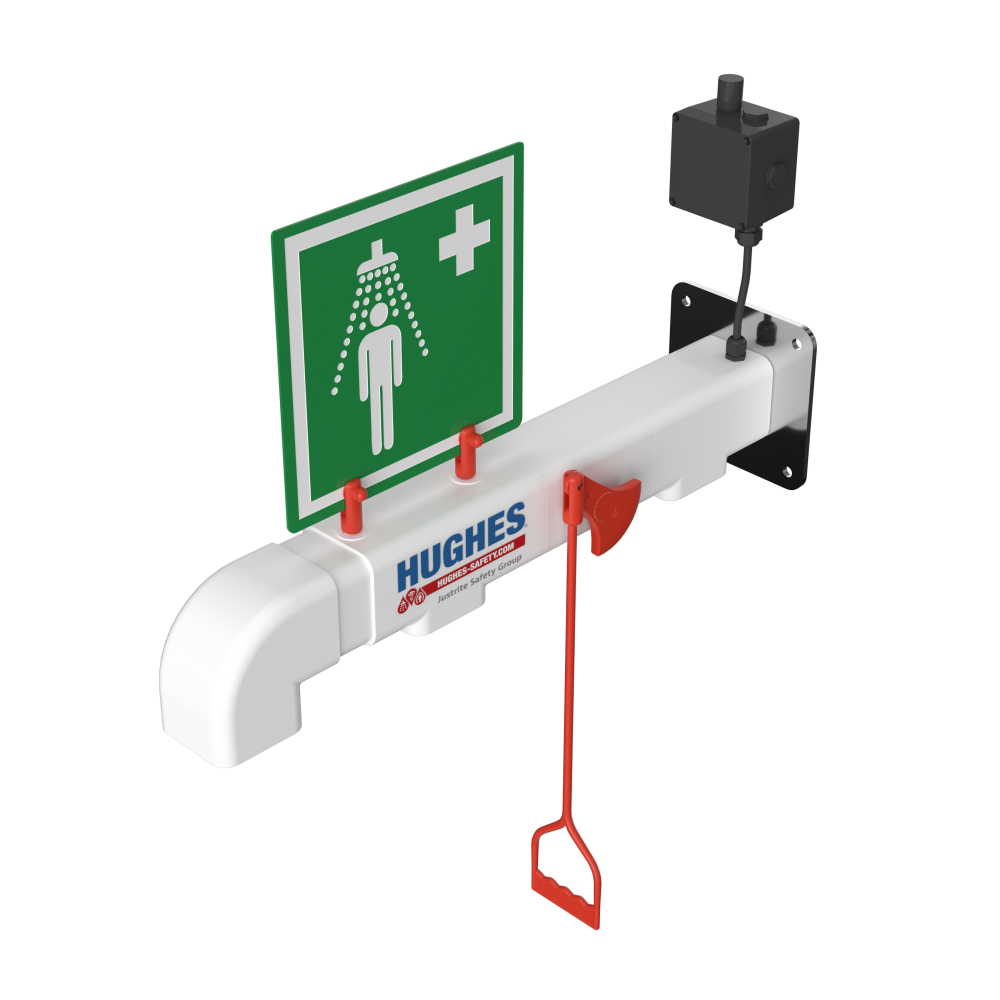

Should a leak occur, safety showers should be positioned within 10 seconds’ reach of any pipework to provide quick relief to affected workers and comply with ANSI standards. ANSI and European standards stipulate that water from a safety shower should be maintained within a tepid range of 59-100F to prevent subjecting them to further harm, such as hypothermia caused by freezing water or scalding due to hot temperature.

Should a leak occur, safety showers should be positioned within 10 seconds’ reach of any pipework to provide quick relief to affected workers and comply with ANSI standards. ANSI and European standards stipulate that water from a safety shower should be maintained within a tepid range of 59-100F to prevent subjecting them to further harm, such as hypothermia caused by freezing water or scalding due to hot temperature.

Hughes manufacture a range of water tempering safety showers. Tubular showers such as the EXP-AH-2GS trace-tape heated wall mounted shower can be installed at the site as a space-saving alternative. The trace-tape heating provides frost protection to the pipework when exposed to extremely cold conditions. On the LNG cargo ships, which are prone to movement from the water, a plumbed-in safety shower is mandatory. In such environments, the STD-SD-32K/45G cubicle safety shower provides a dedicated demarcation zone for decontaminating and comes with an internal eye wash as an all-in-one solution.

For remote regions without a reliable water source Hughes offer a range of immersion-heated emergency tank showers. The 1500L variant ensure compliance to all standards by providing over 15 minutes of water to thoroughly decontaminate the user. An internal eye wash is a standard feature of Hughes tank showers, providing an all-in-one safety solution.

To discuss the safety requirements of your site, contact Hughes for a quote and expert advice.